When it comes to backup power, nothing beats the reliability of diesel generators. Whether for industrial sites, hospitals, or remote locations, keeping your generator in peak condition is crucial. Regular Generator Maintenance not only extends the life of your unit but also ensures that it performs when you need it most. In this guide, we’ll break down easy steps to help you maintain your diesel generator like a pro—without needing to be one!

Why Generator Maintenance Is So Important

Think of a diesel generator like a car engine. If you ignore oil changes or filters, performance drops and failure becomes inevitable. Similarly, skipping basic Generator Maintenance can lead to issues like inefficient fuel use, system breakdowns, and unplanned downtime—costing you time and money.

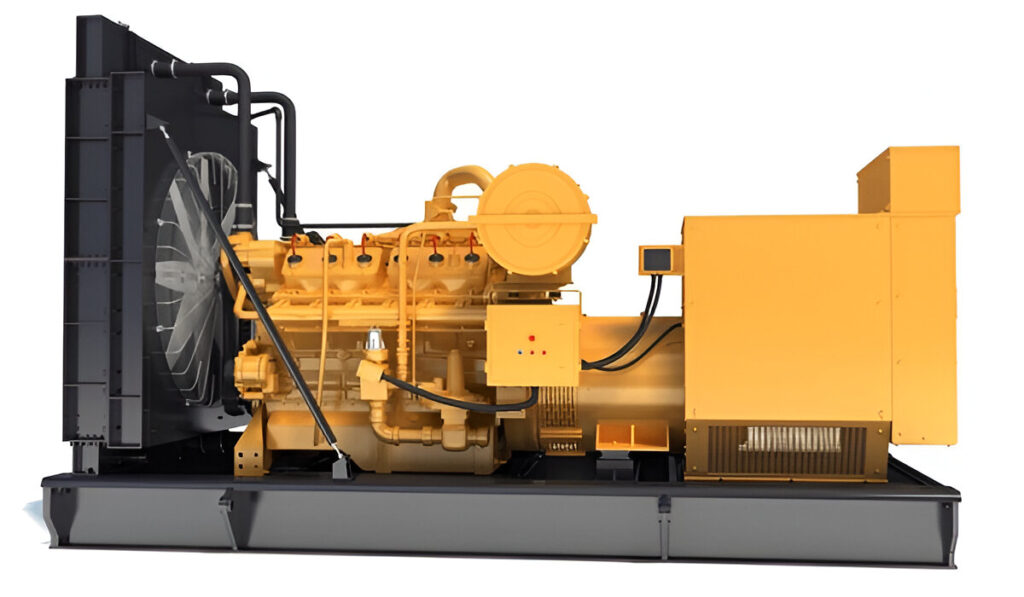

Generators from trusted brands like Caterpillar Generator Company or Cummins are built tough, but even they need regular care to avoid costly repairs or replacements.

Step-by-Step Diesel Generator Maintenance Checklist

1. Check and Change the Oil

Oil is the lifeblood of any diesel motor. Most manufacturers recommend changing the oil every 100-250 hours of operation. Always refer to your user manual for specifics.

- Use manufacturer-approved oil types

- Check oil levels before each use

- Look for signs of sludge or contamination

Keeping the oil fresh ensures smoother engine performance and better fuel economy.

2. Inspect the Fuel System

Diesel can degrade over time, leading to clogged injectors or contaminated filters. Drain the fuel tank periodically and replace filters every 250-300 hours.

Generators like a Diesel Motor Generator are powerful, but even they can be compromised by poor fuel quality. Always use clean diesel fuel and store it properly.

3. Examine the Cooling System

Engines generate a lot of heat. Make sure the coolant level is full and the radiator is clean. Use a 50/50 mix of coolant and distilled water unless otherwise stated.

Look for:

- Cracked hoses

- Rust or scale build-up

- Obstructions in airflow

Blocked airflow or low coolant can overheat your generator and damage internal parts.

4. Test the Battery

A weak or dead battery is one of the most common causes of generator failure. Inspect battery terminals for corrosion and check voltage levels monthly.

- Clean terminals with a baking soda solution

- Tighten loose cables

- Replace old batteries every 2-3 years

For long-term reliability, consider investing in Generator Enclosure systems that protect against environmental damage.

5. Check Belts and Hoses

Belts that drive cooling fans or alternators can wear out over time. If they’re loose or cracked, replace them immediately.

Do the same for hoses—soft, brittle, or bulging ones are at risk of failure under load.

6. Run the Generator Weekly

Even if you’re not using it, you should still run your generator at least once a week for about 15-30 minutes.

Why?

- Prevents fuel from settling

- Keeps engine parts lubricated

- Helps identify any unusual noises or issues early

This small task is one of the most effective ways to ensure generator readiness.

Signs Your Generator Needs Immediate Attention

Even with routine Generator Maintenance, problems can arise. Keep an eye out for:

- Black smoke during operation

- Unusual noises or vibrations

- Leaking fluids

- Hard starting or stalling

- Excessive fuel consumption

If any of these occur, consult a certified technician immediately.

Bonus Tips for Long-Term Generator Health

- Log every inspection or service activity

- Replace air filters every 200-300 hours

- Store spare parts like belts, oil, and filters

- Keep your generator clean and free of debris

Reliable power isn’t just about owning a unit—it’s about maintaining it smartly. Whether you’re using a portable generator or a heavy-duty Generator for Sale, the principles remain the same.

When to Call the Pros

Some things—like a complete engine overhaul or electrical calibration—should be left to professionals. If you’re using high-capacity equipment such as a Diesel Generator for Sale in an industrial setup, it’s smart to schedule professional servicing twice a year.

Certified technicians will:

- Run load tests

- Check alternator performance

- Validate safety systems

- Inspect control panels and wiring

Hiring a pro may cost you upfront, but it saves thousands by preventing major breakdowns later.

Final Thoughts

If you treat your diesel generator well, it will return the favor when you need it most. Regular Generator Maintenance isn’t just a task—it’s an investment in safety, efficiency, and peace of mind.

From weekly run tests to keeping an eye on belts and filters, these simple habits can drastically extend the life of your generator. Whether you’re running a home backup system or managing a commercial power solution, maintenance should never be ignored.

And if you’re in the market for a reliable upgrade, consider exploring options like Used Generators for Sale that offer value and durability.