Operating a diesel generator is a critical responsibility that requires more than just basic knowledge of machinery. Whether you’re using a diesel motor generator for industrial backup power or a temporary power solution at a remote site, ensuring proper safety training for all operators is essential. At BC GENERATORS, we understand the importance of protecting your team, equipment, and investments. This article explores the vital aspects of safety training for diesel generator operators and how it contributes to efficient, reliable, and safe operations.

Why Safety Training Is Crucial for Generator Operators

Diesel generators are powerful machines that can produce high voltage electricity and significant heat. Without the right training, operators can face numerous hazards, including:

- Electrical shocks

- Burns from hot surfaces

- Fuel leaks and fires

- Exposure to carbon monoxide

- Mechanical injuries from moving parts

Proper safety training significantly reduces the risk of accidents and ensures that operators are prepared to handle emergencies and maintain the generator efficiently.

Core Components of Diesel Generator Safety Training

A comprehensive safety training program for diesel generator operators should cover the following areas:

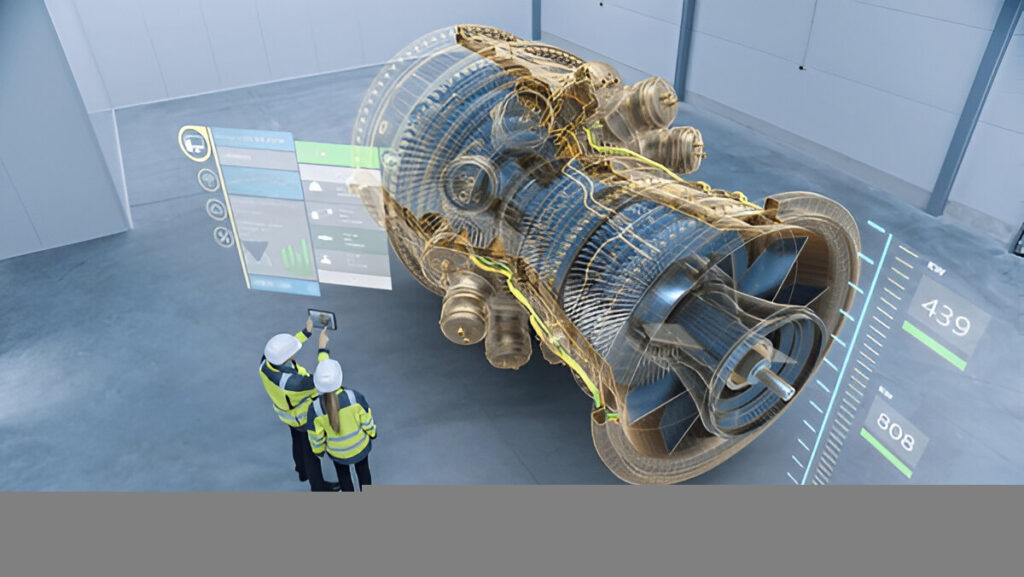

1. Understanding Generator Components

Operators must be familiar with all key components of a generator, including:

- The diesel engine

- Alternator

- Control panel

- Fuel system

- Generator enclosure and ventilation systems

Knowing how each part functions helps operators detect issues early and understand proper maintenance routines.

2. Manufacturer-Specific Guidelines

Different generator models come with unique specifications. Whether you’re working with a Caterpillar generator company unit or a Cummins generator in Canada, operators must review and follow the manufacturer’s safety guidelines. These may include load capacity limits, operating temperatures, and maintenance intervals.

3. Pre-Operational Safety Checks

Before starting any diesel fueled generator, a thorough inspection is crucial. Operators should be trained to:

- Check fuel and oil levels

- Inspect belts and hoses for wear

- Ensure the area is well-ventilated

- Verify that all protective guards are in place

- Check for any fuel or coolant leaks

This routine helps prevent malfunctions and extends the lifespan of your generator.

4. Personal Protective Equipment (PPE)

Diesel generator operators must wear appropriate PPE, including:

- Insulated gloves

- Safety goggles

- Ear protection (especially for generators without a generator enclosure)

- Steel-toe boots

- Flame-resistant clothing

Training should stress the importance of consistent PPE usage to minimize the risk of injury.

5. Safe Operation Procedures

Operators must be trained on:

- Proper start-up and shutdown procedures

- Load management to avoid overloading

- Emergency stop functions

- Handling abnormal operating conditions

For example, during heavy load conditions, a diesel motor generator may require specific adjustments to avoid overheating or engine stress. Operators must know how to make these adjustments safely.

6. Fuel Handling and Storage

Diesel is flammable and must be handled with care. Training should include:

- Safe fuel storage regulations

- How to handle spills or leaks

- Refueling procedures (never during operation)

- Proper disposal of fuel-contaminated materials

Poor fuel handling is a major cause of generator-related fires. Safety training ensures your team understands how to mitigate these risks.

7. Ventilation and Carbon Monoxide Awareness

Diesel generators emit carbon monoxide (CO), an odorless and potentially deadly gas. Operators should understand:

- The dangers of CO exposure

- How to position generators in well-ventilated areas

- Proper use of CO detectors around workspaces

- Signs of CO poisoning (e.g., headaches, dizziness, nausea)

Even portable units or a used generator for sale must be operated in environments that allow adequate airflow.

Specialized Training for Different Generator Types

Different generator brands and configurations require tailored safety approaches. For example:

- Caterpillar generator company models may offer advanced control systems, requiring specific training on digital diagnostics.

- Cummins generator Canada units may have emissions systems that need regular monitoring to remain compliant with environmental regulations.

Whether your organization uses a brand-new model or a used generator for sale, safety training must be adapted accordingly.

Maintenance Safety

Routine maintenance is essential for longevity and reliability, but it also introduces potential hazards. Training should emphasize:

- Lockout/tagout procedures before performing maintenance

- Safe battery handling

- Cleaning techniques without damaging sensitive parts

- Identifying worn parts or dangerous buildup (e.g., soot or corrosion)

Operators should also be instructed on when to call a certified technician for more complex maintenance tasks.

Emergency Procedures

Every operator should be prepared for unexpected events. Your safety training should include:

- Fire suppression techniques and extinguisher types

- First aid basics

- Generator shutdown during power surges or faults

- How to contact emergency services with the correct location and equipment details

Having a clear, practiced emergency response plan can prevent a minor issue from escalating into a major crisis.

Refresher Courses and Certification

Safety training is not a one-time event. Diesel generator operators should receive ongoing refresher courses, especially when:

- New equipment is introduced

- Regulations change

- Accidents or near-misses occur

- Roles within the team are updated

Certification ensures accountability and encourages operators to stay up to date on best practices.

Choosing the Right Equipment Matters

Safety starts with selecting the right equipment. Whether you’re shopping for a generator for sale for your commercial property or looking for a quiet, enclosed model, BC GENERATORS offers a wide selection of reliable products. Our inventory includes diesel fueled generators, trusted brands like Caterpillar and Cummins, and options such as generator enclosures to help reduce noise and improve operator safety.

Final Thoughts

Proper safety training for diesel generator operators isn’t just about following rules—it’s about fostering a safety-first culture that protects people, equipment, and productivity. With the right training, operators can manage even the most powerful diesel motor generators confidently and competently.

If you’re investing in a generator for sale or considering upgrading to newer technology, be sure to pair your purchase with professional training and support. At BC GENERATORS, we’re committed to powering your operations safely and reliably.